Filtration Case Study

The Challenge

BioChem Water was contacted by a large mining company to seek assistance with the declining water quality of their gas seal water. The water was analysed and determined to have increased levels of Fe and suspended solids.

The water was quite turbid and orange in appearance from the Fe oxide and this was due to the system having dissimilar metallurgy. Microbial analyses also indicated a high-level microbial count in the millions.

Based on the water analyses provided, it appeared that several fundamental issues were leading to a deteriorating water quality including the following:

- High Conductivity including chloride levels that contribute to pitting

- Suspended Solids were high, therefore contributing to under deposit corrosion

- High Microbial count contributing to low pH levels

Testing of the pH indicated a level of 5.9 and based on this and alkalinity, the Langelier Saturation Index indicated that the process water was corrosive. As water evaporated from the system, dissolved solids (such as calcium, magnesium, chlorides, sulphate and silica) were remaining in the recirculating water.

Langelier Saturation Index testing with the addition of Sodium Bicarbonate to increase the pH to 8.0 indicated a significant decrease in the corrosivity of the water and that this may be an option other than an organic corrosion inhibitor (environmental factors meant that standard chemical treatment could not be applied).

Controlled monitoring of the quantity of bleed provided the most significant opportunity to control system ion levels, including chloride levels.

At 3,370,000cfu, the Microbial count was significant and increased the amount of carbon dioxide within the system. This, coupled with dissolved oxygen, produced corrosive carboxylic acid.

The high organic load within the system also contributed to under deposit corrosion. This organic load is made up of suspended solids from the raw water, decaying bacteria and also accumulative solids from the process such as iron etc.

Each of these fundamentals were a contributing factor and elimination of each of these lead to a much-improved process water performance.

The BioChem Water Solution

A temporary filtration system was supplied and, as standard 240v power was not allowed, we utilised a Turbidex resin with manual backwash valves.

Turbidex’s enhanced ability to remove sediment results in enhanced water clarity and downstream cost savings on ongoing filter bag replacement, cleaning chemicals and an overall reduction in expensive parts replacement due to under deposit corrosion.

Turbidex is a natural ore called clinoptilolite that has many advantages over common granular filter sands and multimedia used for suspended solids reduction.

Viewed under an electron scanning microscope, the granules reveal an angular shape, rough surface and microporous void spaces as small as 3 microns.

This creates a surface area over 100 times greater than silica sand utilised in conventional sand filters.

The angularity of the granules and the tapered internal pore spaces allow for reduction of dirt, silt and organic matter suspended in water by bridging, straining and adhesion.

The rough surface and internal porosity provide a high surface area for efficient reduction of suspended matter.

Utilising deep bed filtration can typically reduce suspended solids down to the 5 micron absolute and therefore reduce the load on the system and also the biological load that impacts the system.

The Result

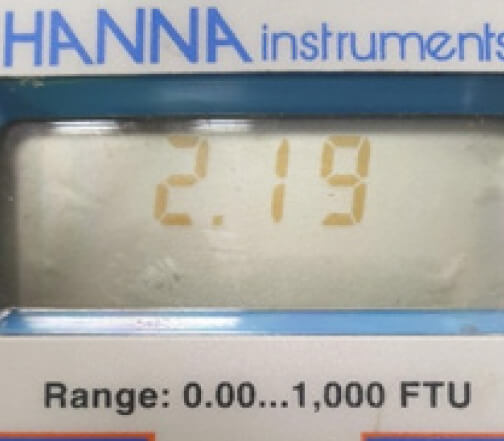

After two weeks of filtration at 7m3 per hour the turbidity had reduced significantly.

After four weeks the turbidity had reduced to 2.19FTU.

12.58FTU after 2 weeks of filtration

2.19FTU after 4 weeks of filtration

Gas seal return water

Temporary filtration system with manual backwash valves

“Following completing a detailed engineering review to establish the cause of (premature) failure of the site’s liquid ring gas pumps, BioChem Water were engaged to provide a water treatment and filtration solution to meet the pump manufacturer’s water quality specifications. BioChem were selected based on their technical expertise, transparency and honesty throughout the tender process. Since partnering with BioChem, Richard and his team have worked closely with the site engineers to seamlessly integrate the water treatment infrastructure and supported the site in every aspect to deliver an unparalleled result. I have no hesitation in declaring BioChem as our preferred partner for water management solutions.”

Grant Marshall, Gas Seal Engineer